Facility – Torr Engineering

At Torr Engineering, we pride ourselves not only on our cutting-edge engineering but also on the robust infrastructure that backs it all up. Our facility is designed to uphold the highest standards in vacuum system performance testing and tailored engineering solutions. With top-notch test rigs, advanced diagnostic tools, and exceptional manufacturing capabilities, we make sure that every product we deliver undergoes rigorous evaluation for quality, performance, and reliability.

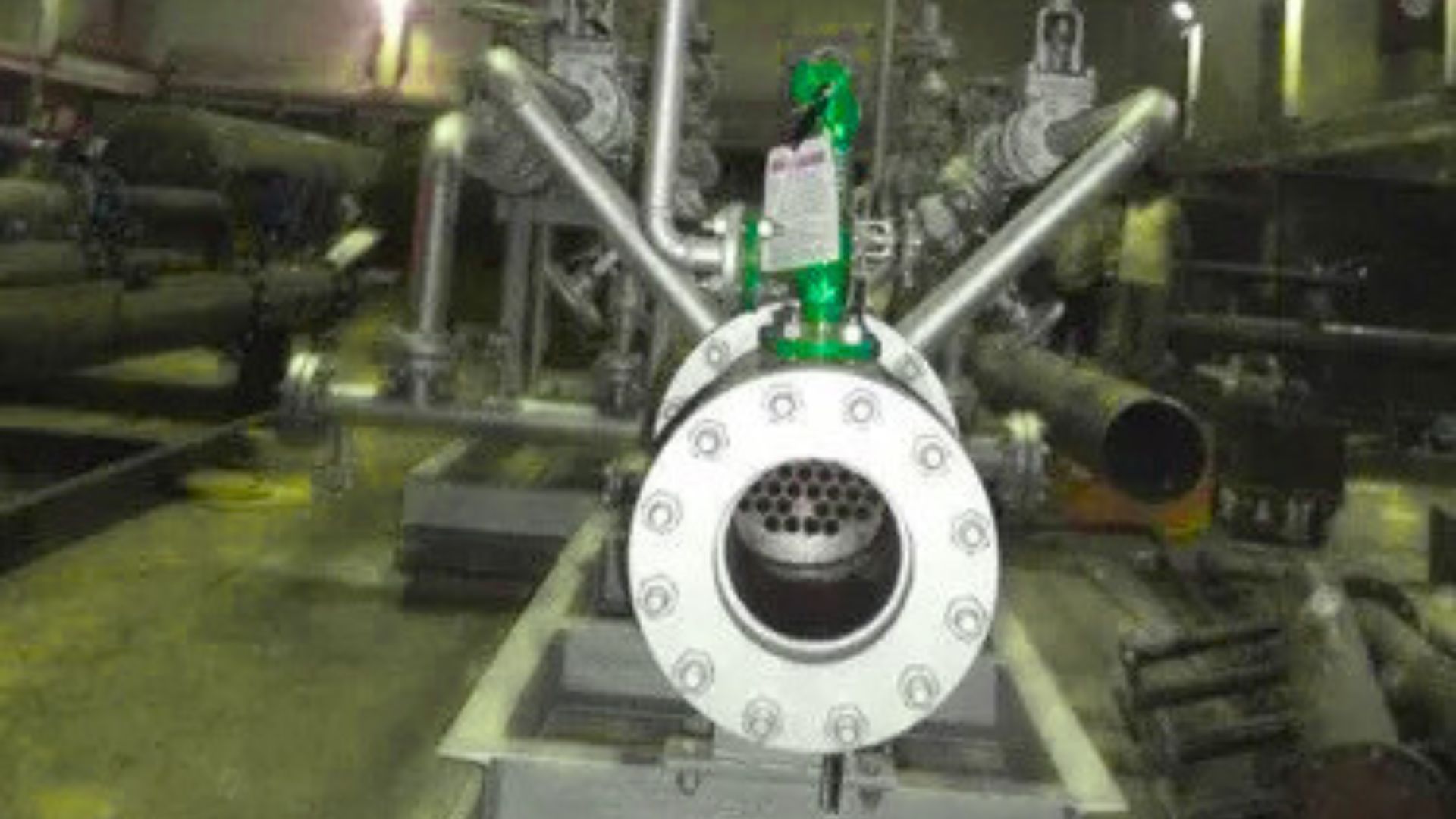

Research & Testing Centre

At Torr Engineering, our cutting-edge Research & Test Facility ensures top-tier quality and verified performance. Our state-of-the-art test plant allows us to simulate real-world operating conditions and analyze critical performance variables.

Key Capabilities:

Measuring ejector suction flow capacity and stability under varying steam and water conditions

Monitoring steam consumption and power usage per ASME PTC‑24 and industry standards

Capturing flow-generated noise data during atmospheric discharge testing

Facility Highlights:

Boilers generating up to 10,000 kg/hr at 17.5 kg/cm²

Cooling towers with a combined capacity of 1,200 TR

Troubleshooting & Diagnostic Support

Our expert team handles both routine and emergency troubleshooting for ejector systems. Whether it’s performance degradation or sudden issues, we methodically investigate:

External factors:

Low or fluctuating steam pressure

Wet steam conditions

Inadequate cooling water flow or high temperatures

Entrained air in condensate

Elevated discharge pressure

Transient loads or excessive air ingress

Internal factors:

Corrosion or erosion of nozzles/diffusers

Clogs in strainers or internal passages

Steam chest leakage

Fouled or blocked cooling water circuits

Cracked or worn components

Inter‑condenser nozzle damage

On-Site Field Service

Our highly trained engineering team is ready for prompt deployment globally. We offer:

Supervision of vacuum system installation

Pre-commissioning & commissioning support

On-demand inspection, cleaning, and recalibration

Maintenance of steam lines and condensers

Full technical reporting and operational recommendations

Backed by certified field agents and supported by the latest diagnostic tools, we ensure your systems run smoothly and efficiently.

Manufacturing & Fabrication Facilities

Our in-house workshop features:

CNC cutting and welding lines

Heavy-plate machining

Fabrication bays for custom ejectors, condensers, and vacuum systems

Quality assurance systems in compliance with ISO, ASME U‑stamp, and NB pressures regs

For those interested in global standards of vacuum testing and ejector performance evaluation, you can refer to:

This standard outlines performance testing for steam jet vacuum systems and is useful for engineers and quality auditors.